Inline Duct Fans Explained: Types, Benefits & Installation Tips

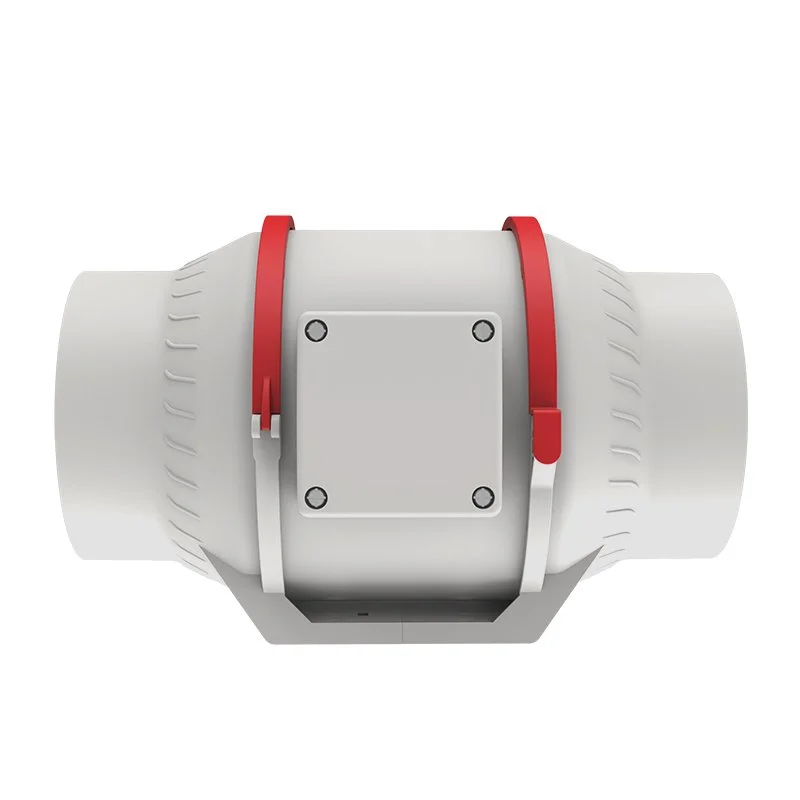

An inline duct fan is a cylindrical fan installed inside ductwork to enhance air movement. Unlike traditional exhaust fans, these units are mounted directly within the duct, making them ideal for long ventilation runs where airflow resistance is an issue.

How Does an Inline Duct Fan Work?

Air Intake – The fan pulls air from one end of the duct.

Boosted Airflow – The internal blades propel air forward.

Exhaust – The air is pushed out the other end, improving ventilation.

These fans are commonly used in:

HVAC systems (heating, ventilation, and air conditioning)

Grow rooms & hydroponics (for temperature and humidity control)

Bathroom & kitchen exhaust systems

Industrial ventilation (factories, warehouses)

Benefits of Using an Inline Duct Fan

Why should you consider installing an inline duct fan? Here are the top advantages:

✅ Improved Airflow Efficiency – Helps overcome resistance in long duct runs.

✅ Energy-Efficient – Many models use low-power motors, reducing electricity costs.

✅ Quiet Operation – Modern designs minimize noise, making them ideal for homes.

✅ Space-Saving – Installed within ducts, saving room compared to bulky external fans.

✅ Versatile Applications – Works in HVAC, grow rooms, exhaust systems, and more.

Types of Inline Duct Fans

Not all inline duct fans are the same. Here are the most common types:

1. Centrifugal Inline Fans

Best for high-pressure applications (e.g., long duct runs with bends).

More powerful but slightly noisier.

2. Axial Inline Fans

Ideal for high airflow with low resistance (e.g., straight duct runs).

Energy-efficient and quieter than centrifugal fans.

3. Mixed Flow Inline Fans

A hybrid of axial and centrifugal designs.

Balances airflow and pressure, making them versatile.

4. EC (Electronically Commutated) Fans

Ultra-energy-efficient with variable speed control.

Great for smart HVAC systems.

How to Choose the Best Inline Duct Fan

Selecting the right inline duct fan depends on several factors:

🔹 Duct Size – Match the fan diameter (4”, 6”, 8”, 10”, etc.) to your ductwork.

🔹 CFM (Cubic Feet per Minute) – Higher CFM = stronger airflow.

🔹 Static Pressure – Important for ducts with bends or long runs.

🔹 Noise Level (dB) – Look for quieter models (under 50 dB) for residential use.

🔹 Energy Efficiency – EC motors save power over time.

Pro Tip: For grow rooms, choose a fan with a speed controller to adjust airflow as needed.

Installation & Maintenance Tips

Installing Your Inline Duct Fan

Turn Off Power – Safety first!

Measure & Cut Duct – Ensure a snug fit.

Secure with Clamps – Use metal clamps for durability.

Wire According to Manual – Follow electrical guidelines.

Test Before Finalizing – Check for vibrations or unusual noise.

Maintenance for Longevity

Clean Regularly – Dust buildup reduces efficiency.

Check for Leaks – Seal gaps in duct connections.

Inspect Motor & Blades – Replace worn-out parts as needed.

Frequently Asked Questions (FAQs)

Q: Can an inline duct fan replace an exhaust fan?

A: Yes! It enhances airflow better than a standard exhaust fan, especially in long ducts.

Q: How long do inline duct fans last?

A: With proper maintenance, they can last 5-10 years.

Q: Are inline duct fans noisy?

A: Modern models are designed for quiet operation—look for ones under 50 dB.

Q: Can I use an inline duct fan for cooling?

A: Absolutely! They improve air circulation, helping with cooling in grow rooms and homes.

Conclusion

An inline duct fan is a game-changer for improving airflow in HVAC systems, grow rooms, and ventilation setups. Whether you need better exhaust, cooling, or air circulation, choosing the right fan will optimize performance and energy efficiency.

Ready to upgrade your ventilation? Browse top-rated inline duct fans today and enjoy better airflow tomorrow!